Overview:

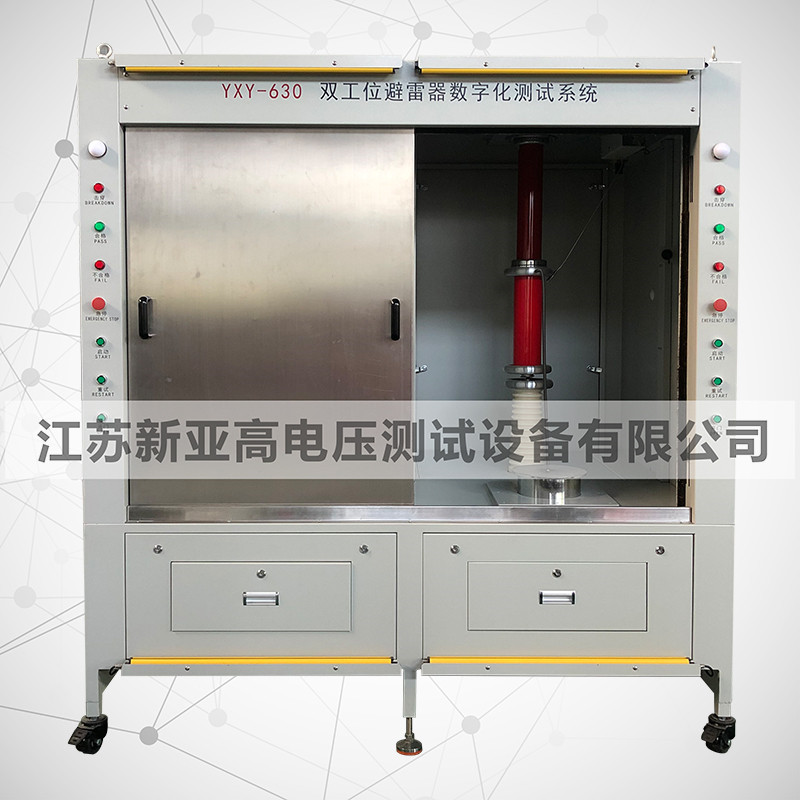

The digital test system is mainly used to test the insulation level of arrester under power frequency high voltage, such as power frequency withstand voltage test, partial discharge test and leakage current test. It has intelligent automatic partial discharge and AC voltage test under AC reference current. The measurement and control part of the whole system runs under the environment of win 10. The network interface is used to communicate between the upper computer and the lower computer. The whole set of equipment is mainly composed of control cabinet and double operation station cabinet. The control cabinet mainly contains digital partial discharge detection part, voltage rise and fall control, data signal processing, communication processing and adjustable power supply; the sample tooling cabinet contains power filter, no partial discharge test transformer, no partial discharge protection resistance, no partial discharge high-voltage reactor, no partial discharge coupling capacitor and voltage divider, input unit, test sample tooling, current and voltage acquisition device Signal switching device, etc.

System functional characteristics

1. The system contains two shielding operation stations. Station 1 and station 2 can be interlocked for power frequency withstand voltage and partial discharge test.

2. Automatic generation of test report, with the function of generating test report (if you need to print, the user should provide a printer).

3. The test efficiency is high, which can meet the needs of rapid factory inspection. In the process of the left station test, the right station can install the test object; when the left station test is finished, the right station can immediately test, and at the same time, it can install the test object again for the left station, saving more than half of the time compared with the normal test process.

4. At the end of the test of each station, it can automatically judge whether the test results are qualified or not, so as to distinguish the quality of the tested products conveniently and quickly.

5. The main circuit adopts three-stage filtering and metal shielding treatment of duplex position cabinet, which can effectively suppress the space interference and reduce the background noise of partial discharge to meet the requirements of test space environment.

The efficiency improvement of the double station test process is as follows:

Assuming that the product is loaded and picked up for 30s, it takes 1 minute to test the product, and the traditional test process takes 4 minutes to test two products completely. However, when the duplex bit is tested in one of the positions, the other station can extract and install the test products. The four products can be tested completely in 4 minutes, which greatly improves the test efficiency of the product. The test ability of the dual station is the traditional test Twice as much as the trial mode.